The Unsung Hero: Exploring the Vital Role of the Pencil Metal Part

When we think of pencils, the image that usually comes to mind is a wooden casing surrounding a graphite core. However, a critical, often overlooked component ensures the pencil’s functionality and longevity: the pencil metal part. This seemingly insignificant piece of metal plays a crucial role in holding the graphite securely, allowing for smooth writing and drawing, and preventing breakage. This article delves into the various aspects of the pencil metal part, exploring its design, materials, manufacturing process, and its impact on the overall quality and performance of a pencil. We’ll also look at the evolution of this component and consider future innovations.

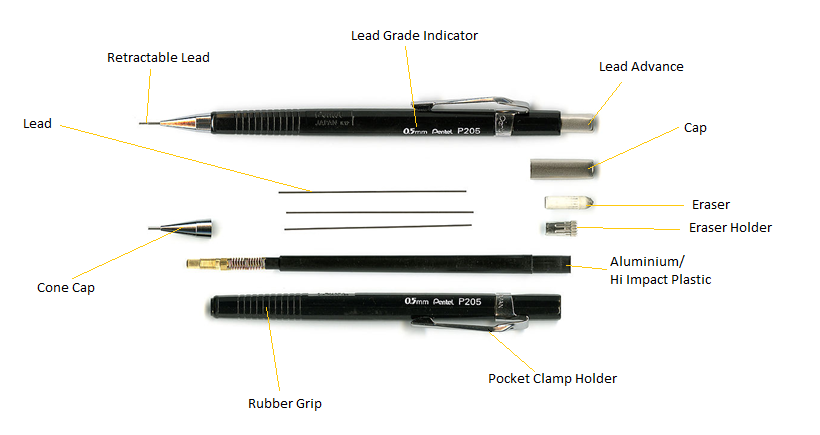

A Closer Look at the Anatomy of a Pencil

Before focusing on the pencil metal part, let’s briefly examine the anatomy of a standard pencil. A typical pencil consists of the following parts:

- Wood Casing: Provides structural support and a comfortable grip.

- Graphite Core: The writing material, made of graphite and clay.

- Adhesive: Holds the graphite core within the wood casing.

- Ferrule: The pencil metal part that clamps the wood casing to the eraser (if present).

- Eraser (Optional): Used for correcting mistakes.

The ferrule, that aforementioned pencil metal part, is our primary focus. It’s the small, often crimped, metal band that connects the wooden body of the pencil to the eraser or simply reinforces the end of the pencil. Its importance is often underestimated, yet without it, the pencil’s structural integrity would be severely compromised.

The Importance of the Pencil Metal Part (Ferrule)

The pencil metal part, or ferrule, provides several key functions:

- Structural Support: It reinforces the wood casing, preventing it from splitting or cracking, especially when sharpened.

- Graphite Retention: It helps to keep the graphite core securely in place, preventing it from sliding out or breaking.

- Eraser Attachment: In pencils with erasers, the ferrule provides a secure anchor point for the eraser.

- Aesthetic Appeal: While primarily functional, the ferrule also contributes to the overall aesthetic of the pencil.

Without a well-designed and properly attached pencil metal part, a pencil would be prone to breakage, making it difficult and frustrating to use. A quality ferrule ensures that the pencil can withstand the pressures of sharpening and writing, providing a reliable and consistent writing experience.

Materials Used in Pencil Metal Parts

The choice of material for the pencil metal part is crucial for its performance and durability. Common materials include:

- Aluminum: Lightweight, corrosion-resistant, and relatively inexpensive. Aluminum ferrules are commonly used in mass-produced pencils.

- Brass: Stronger and more durable than aluminum, brass ferrules provide excellent support and a premium feel. They are often used in higher-quality pencils.

- Steel: Offers the highest strength and durability, but is also more expensive and heavier than aluminum or brass. Steel ferrules are typically found in specialized pencils, such as those used for drafting or engineering.

- Other Metals: Some manufacturers may use other metals or alloys, depending on the desired properties and cost considerations.

The selection of the appropriate metal depends on factors such as the intended use of the pencil, the desired level of durability, and the overall cost target. The pencil metal part needs to withstand regular use and sharpening, thus influencing the decision-making process.

Manufacturing Process of Pencil Ferrules

The manufacturing process of pencil metal parts typically involves the following steps:

- Material Selection: Choosing the appropriate metal based on the desired properties.

- Cutting and Forming: The metal is cut into strips and formed into the desired shape, typically a small tube or band.

- Crimping or Shaping: The ferrule is crimped or shaped to fit snugly around the wood casing and eraser (if present).

- Finishing: The ferrule may be polished, plated, or painted to improve its appearance and corrosion resistance.

- Assembly: The ferrule is attached to the pencil using adhesive or mechanical means.

Modern manufacturing processes often involve automated machinery to ensure consistent quality and high production volumes. Precision is key to ensure that the pencil metal part fits properly and functions effectively.

The Evolution of the Pencil Metal Part

The design and materials used in pencil metal parts have evolved over time. Early pencils often lacked ferrules, relying solely on adhesive to hold the graphite core in place. This made them prone to breakage and limited their lifespan. The introduction of the ferrule was a significant advancement, improving the durability and usability of pencils. Over time, manufacturers have experimented with different metals, shapes, and attachment methods to optimize the performance of the pencil metal part.

Today, we see a wide variety of ferrule designs, ranging from simple, utilitarian bands to more elaborate and decorative styles. Some manufacturers even offer custom ferrules with engraved logos or other personalized features. The evolution continues, driven by the desire for improved performance, aesthetics, and sustainability.

Impact on Pencil Quality and Performance

The quality of the pencil metal part directly impacts the overall quality and performance of the pencil. A poorly made or improperly attached ferrule can lead to several problems:

- Breakage: The wood casing may split or crack, especially during sharpening.

- Graphite Slippage: The graphite core may slide out or break, making it difficult to write or draw.

- Eraser Detachment: The eraser may fall off, rendering it useless.

- Uneven Sharpening: A loose or misaligned ferrule can cause uneven sharpening, resulting in a broken or unusable pencil tip.

Conversely, a well-made and properly attached pencil metal part ensures that the pencil performs optimally, providing a smooth, consistent, and reliable writing experience. It’s a testament to the idea that even the smallest component can have a significant impact on the overall quality of a product.

Future Innovations in Pencil Ferrules

While the basic function of the pencil metal part remains the same, there is always room for innovation. Future developments may focus on:

- Sustainable Materials: Exploring the use of recycled metals or bio-based materials to reduce the environmental impact of pencil manufacturing.

- Improved Attachment Methods: Developing more secure and durable attachment methods to prevent ferrule detachment.

- Ergonomic Designs: Creating ferrules with improved grip and comfort for extended use.

- Smart Ferrules: Integrating sensors or other electronic components into the ferrule to provide feedback on pencil usage or sharpening needs.

These innovations could lead to more sustainable, durable, and user-friendly pencils in the future. The humble pencil metal part, often overlooked, will continue to play a vital role in shaping the future of writing and drawing instruments.

Choosing the Right Pencil: Considering the Metal Part

When selecting a pencil, consider the quality of the pencil metal part. Look for ferrules that are securely attached, made of durable materials, and free from defects. A well-made ferrule is a sign of overall pencil quality and will ensure a longer-lasting and more enjoyable writing experience. Don’t underestimate the importance of this small but crucial component. A solid pencil metal part contributes significantly to a pencil’s lifespan and usability. [See also: Best Mechanical Pencils for Artists]

The Unexpected Artistry of the Pencil Metal Part

Beyond its functional role, the pencil metal part can also be viewed as a miniature work of art. The precision with which it’s crafted, the subtle curves and angles, and the smooth finish all contribute to its aesthetic appeal. In some cases, the ferrule is even used as a canvas for decorative designs or personalized engravings. It’s a reminder that even the most utilitarian objects can possess a certain beauty and craftsmanship. Examining a pencil metal part closely reveals the dedication and skill involved in its creation. [See also: History of Pencil Manufacturing]

The Environmental Impact of Pencil Metal Parts

The manufacturing and disposal of pencil metal parts, like any metal component, have an environmental impact. The extraction of raw materials, the energy-intensive manufacturing processes, and the potential for improper disposal all contribute to pollution and resource depletion. It’s important for manufacturers to adopt sustainable practices, such as using recycled materials, minimizing waste, and ensuring proper recycling of used pencils. Consumers can also play a role by choosing pencils made from sustainable materials and properly disposing of used pencils. A conscious effort to reduce the environmental footprint of pencil metal part production and consumption is crucial for a more sustainable future. [See also: Eco-Friendly Writing Instruments]

Conclusion: The Enduring Legacy of the Pencil Metal Part

The pencil metal part, or ferrule, may seem like a small and insignificant component, but it plays a vital role in the functionality, durability, and overall quality of a pencil. From providing structural support to ensuring graphite retention and aesthetic appeal, the ferrule is an essential part of the pencil’s anatomy. As we’ve explored, the design, materials, and manufacturing processes of pencil metal parts have evolved over time, and future innovations promise to further enhance their performance and sustainability. So, the next time you pick up a pencil, take a moment to appreciate the unsung hero – the pencil metal part – that makes it all possible. The humble pencil metal part is a testament to the power of thoughtful design and the importance of even the smallest details. The integrity of the pencil metal part is essential to the longevity and performance of any pencil. Remember the importance of the pencil metal part when selecting writing tools.