The Ultimate Guide to Rusty Bolt Remover: Solutions and Prevention

Dealing with a rusty bolt can be one of the most frustrating experiences for mechanics, DIY enthusiasts, and anyone working with machinery or vehicles. A stubborn, rusty bolt can halt progress, damage equipment, and even cause injury if not handled correctly. That’s why understanding how to effectively use a rusty bolt remover is crucial. This comprehensive guide will delve into various methods for removing rusty bolts, focusing on the best products and techniques available, and how to prevent rust in the first place. We’ll explore everything from chemical solutions to mechanical approaches, ensuring you’re equipped to tackle any rusty bolt challenge.

Understanding Rust and Its Impact

Before diving into solutions, it’s essential to understand what rust is and why it’s so problematic. Rust, or iron oxide, forms when iron or steel is exposed to oxygen and moisture. This electrochemical process weakens the metal, causing it to expand and seize up threads, making bolt removal difficult, if not impossible.

The impact of rust extends beyond mere inconvenience. Severely rusted bolts can compromise the structural integrity of equipment, leading to potential failures and safety hazards. In automotive applications, for example, rusted bolts can affect suspension components, brake lines, and other critical systems.

Chemical Solutions: The Power of Rusty Bolt Removers

Chemical rusty bolt removers are designed to penetrate the rust and break the bond between the bolt and the surrounding material. These products typically come in spray or liquid form and contain solvents, lubricants, and rust inhibitors.

Types of Chemical Rusty Bolt Removers

- Penetrating Oils: These are lightweight oils designed to seep into tight spaces, lubricating the threads and loosening the rust. Popular options include WD-40 Specialist Penetrant, Liquid Wrench, and PB Blaster.

- Rust Converters: These chemicals react with the rust, converting it into a more stable compound that can be painted over. They are ideal for preventing further corrosion after removing the bolt.

- Acid-Based Removers: These are more aggressive solutions that use acids, such as phosphoric or hydrochloric acid, to dissolve the rust. Use with caution and proper safety gear.

How to Use Chemical Rusty Bolt Removers Effectively

- Clean the Area: Remove any loose debris or dirt from around the bolt.

- Apply the Remover: Generously apply the rusty bolt remover to the bolt and surrounding area.

- Wait: Allow the remover to penetrate for the recommended time, usually 15-30 minutes, or longer for severely rusted bolts. Multiple applications may be necessary.

- Tap the Bolt: Gently tap the bolt head with a hammer to help the remover penetrate further.

- Attempt Removal: Use the appropriate wrench or socket to try to loosen the bolt. Apply steady, even pressure.

Mechanical Methods: When Chemicals Aren’t Enough

Sometimes, chemical solutions alone aren’t sufficient to remove a stubborn rusty bolt. In these cases, mechanical methods can provide the necessary force and leverage.

Tools and Techniques

- Impact Wrenches: These powerful tools deliver high torque in short bursts, making them ideal for breaking loose rusted bolts.

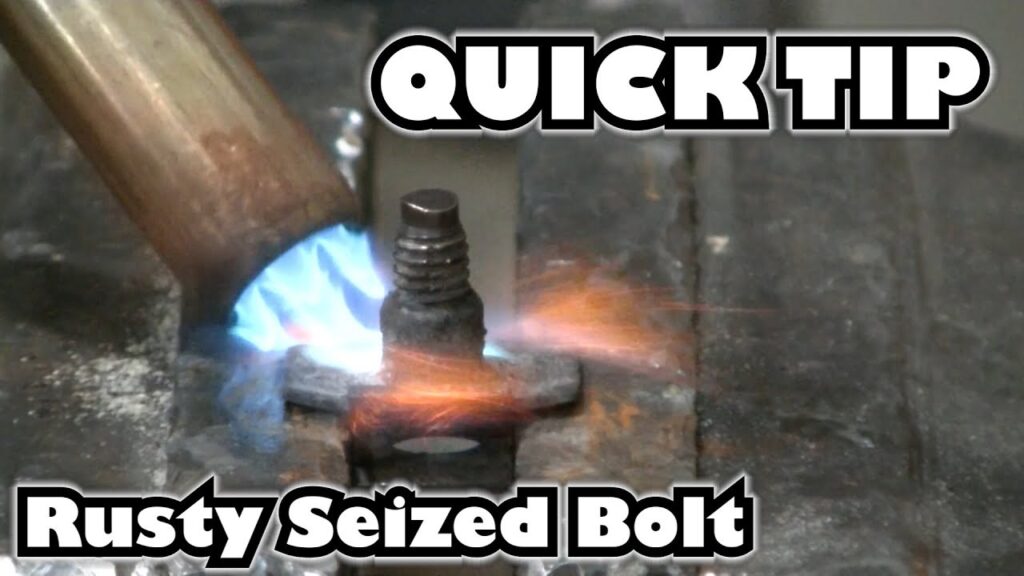

- Heat: Applying heat to the bolt can cause it to expand, breaking the rust bond. Use a propane torch or heat gun, but be cautious around flammable materials.

- Bolt Extractors: These are specialized sockets with reverse threads or gripping teeth designed to bite into the bolt head and provide a secure grip.

- Vice Grips: If the bolt head is severely damaged, vice grips can provide a strong grip for turning.

- Penetrating Oil and Heat Combination: Applying penetrating oil, letting it soak, and then applying heat can dramatically improve the chances of removing a stubborn bolt.

The Importance of Proper Technique

Regardless of the method used, proper technique is crucial to avoid damaging the bolt or surrounding components. Always use the correct size wrench or socket to prevent rounding off the bolt head. Apply steady, even pressure, and avoid jerky movements. If the bolt refuses to budge, don’t force it – try a different method or a combination of methods.

Preventing Rust: A Proactive Approach

The best way to deal with a rusty bolt is to prevent rust from forming in the first place. A proactive approach to rust prevention can save time, money, and frustration in the long run.

Protective Coatings

- Galvanizing: This process involves coating steel with a layer of zinc, which provides a barrier against corrosion.

- Powder Coating: This is a durable coating applied electrostatically and then cured under heat. It provides excellent protection against rust and other environmental factors.

- Paint: Applying a good quality primer and paint can also help protect metal surfaces from rust.

Regular Maintenance

Regular maintenance is essential for preventing rust. This includes:

- Cleaning: Regularly clean metal surfaces to remove dirt, salt, and other contaminants that can promote rust.

- Lubrication: Apply lubricants to bolts and other moving parts to prevent them from seizing up.

- Inspection: Regularly inspect metal surfaces for signs of rust and address them promptly.

Using Stainless Steel Fasteners

Stainless steel is naturally resistant to rust and corrosion, making it an excellent choice for fasteners in environments where rust is a concern. While stainless steel fasteners are more expensive than their carbon steel counterparts, they can provide long-term cost savings by reducing the need for maintenance and replacement.

Choosing the Right Rusty Bolt Remover Product

With so many rusty bolt remover products on the market, choosing the right one can be challenging. Consider the following factors when making your selection:

- Severity of Rust: For lightly rusted bolts, a penetrating oil may be sufficient. For severely rusted bolts, a more aggressive acid-based remover may be necessary.

- Material Compatibility: Ensure the remover is compatible with the materials being used. Some removers can damage certain plastics or paints.

- Safety: Always follow the manufacturer’s safety instructions and wear appropriate protective gear, such as gloves and eye protection.

- User Reviews: Read online reviews to get an idea of the product’s effectiveness and ease of use.

Case Studies: Real-World Examples

Let’s examine a few real-world scenarios where using the right rusty bolt remover made all the difference:

Automotive Repair

A mechanic was struggling to remove a rusted exhaust manifold bolt on an older car. After trying several penetrating oils with limited success, he switched to an acid-based remover. After allowing the remover to soak for several hours, the bolt finally came loose without damaging the manifold.

Marine Maintenance

A boat owner was dealing with severely corroded bolts on the hull. He used a combination of heat and penetrating oil, followed by an impact wrench. The bolts eventually came loose, allowing him to replace the corroded parts and prevent further damage to the boat.

Home Improvement

A homeowner was trying to remove rusted bolts from an old fence. She used a rusty bolt remover spray and a bolt extractor. The bolt extractor provided a secure grip, allowing her to remove the bolts without damaging the fence posts.

Safety Precautions When Using Rusty Bolt Remover

Working with rusty bolt removers and mechanical tools can be hazardous if proper safety precautions are not followed. Always wear appropriate protective gear, such as gloves, eye protection, and a respirator if working with strong chemicals.

Work in a well-ventilated area to avoid inhaling harmful fumes. Be cautious when using heat, and keep flammable materials away from the work area. If using power tools, follow the manufacturer’s safety instructions and use them with care.

The Future of Rust Prevention

As technology advances, new and innovative methods for rust prevention are constantly being developed. These include:

- Nanotechnology Coatings: These coatings provide an ultra-thin, highly effective barrier against rust and corrosion.

- Self-Healing Coatings: These coatings can repair themselves when damaged, providing long-lasting protection.

- Electrochemical Protection: This involves using electrical currents to prevent rust from forming on metal surfaces.

Conclusion: Mastering the Art of Rusty Bolt Removal

Dealing with rusty bolts can be a challenging but manageable task. By understanding the causes of rust, choosing the right rusty bolt remover products and techniques, and taking a proactive approach to rust prevention, you can save time, money, and frustration. Whether you’re a professional mechanic, a DIY enthusiast, or simply someone who wants to keep their equipment in good condition, mastering the art of rusty bolt removal is a valuable skill. Remember to prioritize safety, use the right tools, and don’t be afraid to experiment with different methods until you find what works best for you. By following the tips and techniques outlined in this guide, you’ll be well-equipped to tackle any rusty bolt challenge.

This guide provides a comprehensive overview, ensuring you have the knowledge and resources to effectively handle rusty bolts and prevent future occurrences. Happy wrenching!

[See also: Best Penetrating Oils for Rusted Bolts]

[See also: How to Prevent Rust on Tools]

[See also: Choosing the Right Wrench for Bolt Removal]