The Ultimate Guide to Cleaner Electrical Contacts: Ensuring Optimal Performance

Electrical contacts are the unsung heroes of modern technology. From powering our homes to enabling complex machinery, these seemingly small components play a crucial role in ensuring the flow of electricity. However, over time, electrical contacts can become corroded, dirty, or otherwise compromised, leading to reduced performance, increased resistance, and even complete failure. That’s where a reliable cleaner electrical contact becomes essential. This comprehensive guide will walk you through everything you need to know about maintaining and cleaning electrical contacts, ensuring your systems run smoothly and efficiently.

Why Clean Electrical Contacts Matter

The importance of cleaner electrical contacts cannot be overstated. Dirty or corroded contacts can lead to a host of problems, including:

- Reduced Conductivity: Build-up on the contact surface increases resistance, hindering the flow of electricity.

- Overheating: Increased resistance generates heat, potentially damaging components and creating a fire hazard.

- Intermittent Connections: Dirty contacts can cause inconsistent connections, leading to erratic equipment behavior.

- Equipment Failure: In severe cases, corroded contacts can completely prevent electrical flow, causing equipment to fail.

- Increased Energy Consumption: Systems have to work harder to overcome the resistance, leading to higher energy bills.

Regularly cleaning your electrical contacts is a simple yet effective way to prevent these issues and ensure the longevity and reliability of your electrical systems. Using a specialized cleaner electrical contact product is crucial for achieving the best results without damaging sensitive components.

Identifying the Need for Cleaning

How do you know when your electrical contacts need cleaning? Here are some telltale signs:

- Visible Corrosion: Look for signs of rust, oxidation, or other build-up on the contact surfaces.

- Dimming Lights: If lights connected to the circuit are flickering or dimming, it could indicate a problem with the contacts.

- Erratic Equipment Behavior: Malfunctioning equipment or intermittent operation can be caused by dirty contacts.

- Unusual Heat: If you notice excessive heat near electrical connections, it’s a sign of increased resistance.

- Audible Crackling or Hissing: These sounds can indicate arcing caused by poor contact.

If you observe any of these signs, it’s time to inspect and clean your electrical contacts using a suitable cleaner electrical contact solution. [See also: Electrical Safety Practices]

Choosing the Right Electrical Contact Cleaner

Not all cleaner electrical contact products are created equal. Selecting the right cleaner is essential for effective cleaning and preventing damage to your electrical components. Consider the following factors when choosing a cleaner:

- Type of Contact: Different metals and materials require different cleaning solutions. Check the product label to ensure it’s compatible with your specific contacts.

- Solvent Type: Common solvents include isopropyl alcohol, petroleum distillates, and specialized electronic cleaners. Choose a solvent that effectively removes contaminants without damaging the contact material.

- Residue: Some cleaners leave behind a residue that can attract dirt and debris. Opt for a cleaner that evaporates completely or leaves a minimal, non-conductive residue.

- Safety: Choose a cleaner that is non-flammable and has low toxicity. Always follow the manufacturer’s safety instructions.

- Application Method: Cleaners are available in various forms, including sprays, wipes, and liquids. Choose the application method that is most convenient and effective for your specific needs.

Brands like CRC, DeoxIT, and MG Chemicals are well-regarded in the industry for producing high-quality cleaner electrical contact solutions. Always read reviews and compare products before making a purchase.

Step-by-Step Guide to Cleaning Electrical Contacts

Cleaning electrical contacts is a straightforward process, but it’s essential to follow safety precautions and use the correct techniques. Here’s a step-by-step guide:

Safety First

- Disconnect Power: Always disconnect the power supply to the circuit before cleaning any electrical contacts. This is the most crucial safety precaution.

- Wear Protective Gear: Wear gloves and eye protection to prevent skin and eye irritation from the cleaner.

- Ventilation: Work in a well-ventilated area to avoid inhaling fumes from the cleaner electrical contact.

Cleaning Process

- Inspect the Contacts: Visually inspect the contacts for signs of corrosion, dirt, or other contamination.

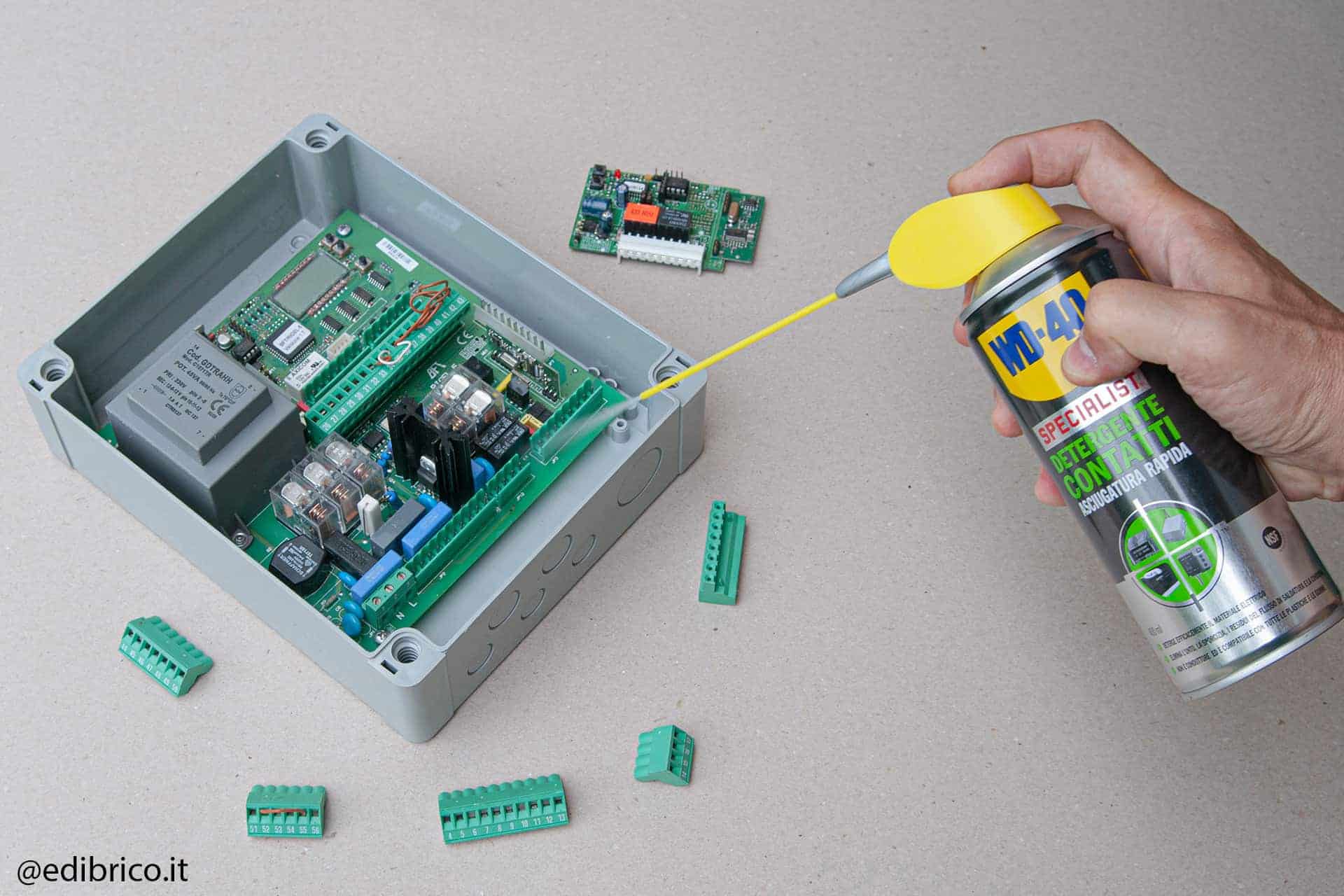

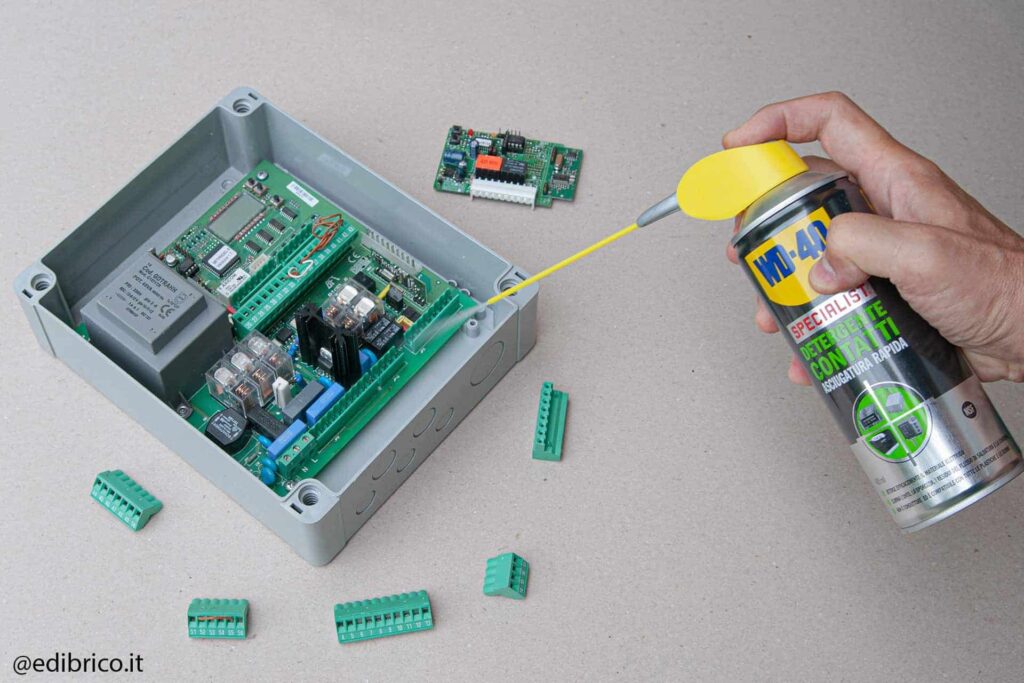

- Apply the Cleaner: Apply the cleaner electrical contact to the contacts using a spray, wipe, or brush, depending on the product and application.

- Scrub Gently: Use a soft brush or lint-free cloth to gently scrub the contacts and remove any stubborn build-up. Avoid using abrasive materials that could damage the contact surface.

- Remove Residue: If the cleaner leaves a residue, wipe it away with a clean, lint-free cloth.

- Allow to Dry: Allow the contacts to dry completely before reconnecting the power.

- Reassemble and Test: Reassemble the components and test the circuit to ensure proper functionality.

For heavily corroded contacts, you may need to repeat the cleaning process or use a specialized corrosion remover. Remember to always follow the manufacturer’s instructions for the specific cleaner electrical contact you are using.

Common Mistakes to Avoid

While cleaning electrical contacts is generally safe, there are some common mistakes to avoid:

- Using Abrasive Cleaners: Abrasive cleaners can scratch and damage the contact surface, leading to increased resistance and reduced performance.

- Applying Too Much Cleaner: Excessive cleaner can seep into sensitive components and cause damage. Use a small amount and apply it carefully.

- Reconnecting Power Too Soon: Reconnecting the power before the contacts are completely dry can create a short circuit or damage the equipment.

- Ignoring Safety Precautions: Failing to disconnect the power or wear protective gear can lead to serious injury.

- Using the Wrong Cleaner: Using an incompatible cleaner can damage the contact material or leave behind a harmful residue.

By avoiding these common mistakes, you can ensure a safe and effective cleaning process and prolong the life of your electrical contacts. Always prioritize safety and follow the manufacturer’s instructions for the cleaner electrical contact you are using.

Preventative Measures

While cleaning electrical contacts is essential, taking preventative measures can reduce the frequency of cleaning and extend the life of your contacts. Here are some tips:

- Use Sealed Connectors: Sealed connectors protect the contacts from moisture, dust, and other contaminants.

- Apply Protective Coatings: Apply a thin layer of protective coating to the contacts to prevent corrosion.

- Regular Inspections: Regularly inspect your electrical contacts for signs of corrosion or dirt.

- Proper Ventilation: Ensure proper ventilation to prevent moisture build-up.

- Avoid Overloading Circuits: Overloading circuits can generate excessive heat, accelerating corrosion.

By implementing these preventative measures, you can minimize the need for frequent cleaning and keep your electrical contacts in optimal condition. A good cleaner electrical contact will still be needed periodically, but preventative actions can make a significant difference.

Advanced Cleaning Techniques

For heavily corroded or hard-to-reach contacts, you may need to employ advanced cleaning techniques. These techniques may require specialized tools and expertise, so it’s essential to proceed with caution.

- Ultrasonic Cleaning: Ultrasonic cleaners use high-frequency sound waves to remove contaminants from the contact surface.

- Microabrasive Blasting: Microabrasive blasting uses a fine stream of abrasive particles to remove corrosion and build-up.

- Chemical Etching: Chemical etching uses corrosive chemicals to remove a thin layer of the contact surface, revealing fresh metal.

These advanced techniques should only be performed by trained professionals. Improper use can damage the contacts or create a safety hazard. If you’re unsure about performing these techniques, consult with a qualified electrician or electronics technician. Even with advanced techniques, finishing with a cleaner electrical contact designed for electronics is advisable.

The Future of Electrical Contact Cleaning

The field of electrical contact cleaning is constantly evolving, with new technologies and techniques emerging all the time. Researchers are exploring new materials and coatings that are more resistant to corrosion and contamination. They are also developing more effective and environmentally friendly cleaner electrical contact solutions.

As technology advances, the demand for reliable and efficient electrical contacts will only increase. Staying informed about the latest developments in electrical contact cleaning will be crucial for maintaining the performance and longevity of your electrical systems. The proper application of a cleaner electrical contact remains fundamental to any maintenance plan.

Conclusion

Maintaining cleaner electrical contacts is a critical aspect of ensuring the reliability and efficiency of your electrical systems. By understanding the importance of clean contacts, choosing the right cleaner, following proper cleaning techniques, and taking preventative measures, you can prolong the life of your equipment and prevent costly failures. Remember to always prioritize safety and consult with a qualified professional if you have any doubts or concerns. Regular maintenance with a quality cleaner electrical contact product is a small investment that can yield significant returns in terms of performance, safety, and longevity.