Mastering the Art of Removing Bolts: A Comprehensive Guide

Removing bolts can seem like a simple task, but anyone who’s wrestled with a stubborn, rusted, or damaged bolt knows it can quickly turn into a frustrating and time-consuming ordeal. This comprehensive guide aims to equip you with the knowledge and techniques needed to tackle even the most challenging bolt removal situations. Whether you’re a seasoned mechanic or a DIY enthusiast, understanding the nuances of removing bolts effectively will save you time, money, and potential damage to your equipment.

Understanding Different Types of Bolts and Their Challenges

Before diving into the techniques, it’s crucial to understand the different types of bolts you might encounter. Common types include hex bolts, carriage bolts, socket head cap screws, and flange bolts. Each type has its specific application and potential vulnerabilities. Rust, corrosion, overtightening, and thread damage are among the most common reasons why removing bolts becomes difficult. Recognizing the potential causes of the problem is the first step toward a successful solution.

Identifying the Problem: Why is the Bolt Stuck?

The first step in removing bolts successfully is to diagnose the problem. Is it simply overtightened? Is there visible rust or corrosion? Is the bolt head stripped? Or is the thread damaged? A careful inspection will guide you to the appropriate removal technique. Ignoring the problem and forcing the bolt can lead to further damage, making the situation even worse.

Essential Tools for Removing Bolts

Having the right tools is paramount for effectively removing bolts. Here’s a list of essential tools you should have in your arsenal:

- Wrenches: A variety of wrenches, including open-end, box-end, and socket wrenches, in both metric and imperial sizes.

- Sockets: A comprehensive socket set with various sizes and drive sizes (1/4″, 3/8″, and 1/2″). Consider impact sockets for use with impact wrenches.

- Penetrating Oil: A high-quality penetrating oil, such as WD-40 Specialist Penetrant or Kroil, is essential for loosening rusted or corroded bolts.

- Heat Gun or Torch: Applying heat can help break down rust and corrosion, making removing bolts easier. Use caution and ensure proper ventilation.

- Bolt Extractors: These specialized tools are designed to grip stripped or rounded bolt heads.

- Vice Grips: Useful for gripping and turning bolts with damaged heads.

- Hammer: A hammer can be used to tap the bolt head to help break the corrosion or to drive a bolt extractor.

- Drill and Drill Bits: For drilling out severely damaged bolts as a last resort.

- Safety Glasses and Gloves: Always prioritize safety when working with tools and potentially hazardous materials.

Techniques for Removing Stuck Bolts

Here are several techniques for removing bolts, ranging from simple to more advanced:

Applying Penetrating Oil

This is often the first and simplest approach. Liberally apply penetrating oil to the bolt threads and allow it to soak for at least 15-30 minutes, or even overnight for heavily corroded bolts. The oil will seep into the threads and help break down the rust and corrosion. After soaking, try removing bolts with a wrench or socket.

Using Heat

Heat can be very effective for removing bolts, especially those that are heavily rusted. Apply heat to the bolt head for a few minutes. The heat will cause the metal to expand, breaking the bond between the bolt and the surrounding material. Be careful not to overheat the bolt, as this can weaken it. After heating, try removing bolts while the metal is still warm.

Tapping the Bolt Head

Sometimes, a few gentle taps with a hammer can help break the corrosion. Use a hammer and punch to tap the bolt head squarely. This can help to loosen the bolt and make it easier to remove. Avoid hitting the bolt too hard, as this can damage the bolt head or surrounding material.

Using a Bolt Extractor

Bolt extractors are designed to grip stripped or rounded bolt heads. There are several types of bolt extractors available, including spiral flute extractors and square extractors. Choose the appropriate extractor for the size and type of bolt you’re working with. Follow the manufacturer’s instructions for using the extractor. Typically, you’ll need to hammer the extractor onto the bolt head and then use a wrench or socket to turn it.

Using Vice Grips

If the bolt head is only slightly damaged, you may be able to use vice grips to grip the bolt head and turn it. Adjust the vice grips to a tight fit and make sure they are securely gripping the bolt head. Apply steady pressure and turn the bolt slowly. Be careful not to damage the bolt head further.

Drilling Out the Bolt

As a last resort, you can drill out the bolt. This is a more advanced technique that requires precision and patience. Start by center-punching the bolt head to create a starting point for the drill bit. Use a drill bit that is slightly smaller than the diameter of the bolt. Drill through the bolt head until you reach the threads. Then, use a screw extractor to remove the remaining bolt. [See also: Removing Stripped Screws]

Preventing Future Problems: Bolt Maintenance and Best Practices

Preventing bolts from seizing in the first place is the best approach. Here are some tips for bolt maintenance and best practices:

- Use Anti-Seize Lubricant: Apply anti-seize lubricant to the bolt threads before installing them. This will help to prevent corrosion and make removing bolts easier in the future.

- Proper Torque: Tighten bolts to the manufacturer’s specified torque. Overtightening can damage the threads and make removing bolts more difficult.

- Regular Inspection: Inspect bolts regularly for signs of rust or corrosion. Replace any damaged or corroded bolts.

- Use the Right Tools: Always use the correct size and type of wrench or socket for the bolt you’re working with. Using the wrong tool can damage the bolt head.

- Clean Threads: Keep threads clean and free of debris.

Safety Precautions When Removing Bolts

Safety should always be your top priority when removing bolts. Here are some safety precautions to keep in mind:

- Wear Safety Glasses: Protect your eyes from flying debris.

- Wear Gloves: Protect your hands from sharp edges and chemicals.

- Work in a Well-Ventilated Area: When using penetrating oil or heat, work in a well-ventilated area to avoid inhaling harmful fumes.

- Use Caution with Heat: Be careful when using a heat gun or torch. Avoid overheating the bolt and be aware of flammable materials in the area.

- Disconnect Power: If working on electrical equipment, disconnect the power before removing bolts.

Troubleshooting Common Bolt Removal Problems

Even with the right tools and techniques, you may still encounter problems when removing bolts. Here are some common problems and solutions:

- Stripped Bolt Head: Use a bolt extractor or vice grips to grip the bolt head.

- Broken Bolt: Use a screw extractor to remove the broken bolt. If the bolt is deeply embedded, you may need to drill it out.

- Rusted Bolt: Apply penetrating oil and heat. Let the oil soak for a long time before attempting to remove the bolt.

- Seized Bolt: Apply penetrating oil, heat, and tap the bolt head with a hammer. If the bolt is still seized, you may need to use a bolt extractor or drill it out.

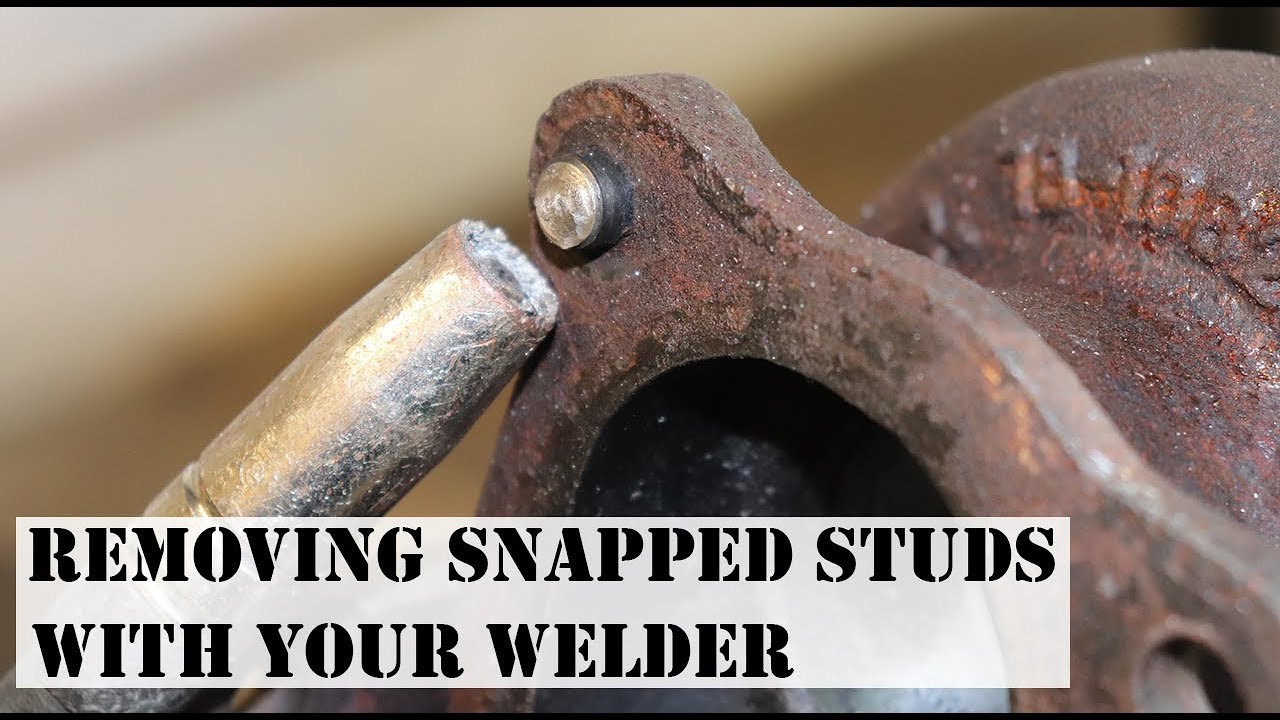

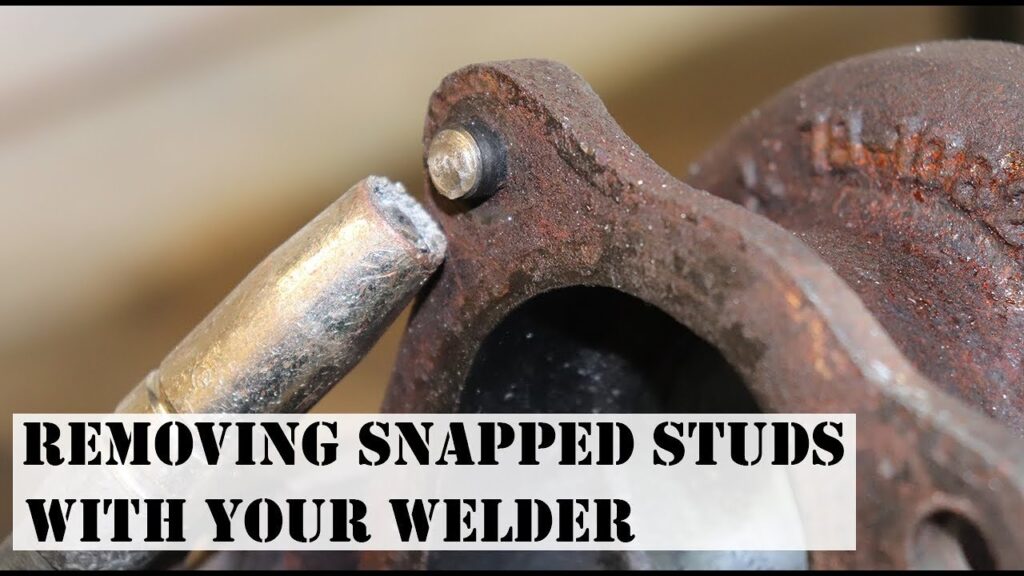

Advanced Techniques for Removing Severely Stuck Bolts

For severely stuck bolts, more advanced techniques may be required. These techniques often involve specialized tools and require more skill and experience.

Using an Impact Wrench

An impact wrench can deliver high torque and rapid impacts, which can help to loosen severely stuck bolts. Use impact sockets with an impact wrench to avoid damaging the sockets. Apply penetrating oil before using the impact wrench.

Using a Nut Splitter

A nut splitter is a tool that is used to split a nut when it is seized onto a bolt. This tool can be helpful when the bolt head is damaged or inaccessible. Be careful when using a nut splitter, as it can damage the threads on the bolt.

Using an Induction Heater

An induction heater is a tool that uses electromagnetic induction to heat metal. This tool can be used to heat the bolt head quickly and evenly, which can help to break the corrosion. Induction heaters are more expensive than heat guns or torches, but they are more effective and safer to use.

Conclusion

Removing bolts doesn’t have to be a daunting task. By understanding the different types of bolts, having the right tools, and using the appropriate techniques, you can tackle even the most challenging bolt removal situations. Remember to prioritize safety and take your time. With practice and patience, you’ll become a master of removing bolts.

Whether you’re dealing with rusted, stripped, or simply stubborn fasteners, this guide provides the comprehensive knowledge you need to succeed. Remember to always prioritize safety and choose the right method for the specific situation. Happy wrenching!