How to Remove a Broken Screw from Metal: A Comprehensive Guide

Dealing with a broken screw stuck in metal can be incredibly frustrating. Whether you’re working on a DIY project, repairing machinery, or tackling a home improvement task, a stripped or snapped screw can bring your progress to a grinding halt. Fortunately, there are several methods you can employ to remove broken screw from metal without causing further damage. This comprehensive guide will walk you through various techniques, tools, and tips to successfully extract that stubborn screw and get your project back on track.

Understanding the Problem: Why Screws Break

Before diving into the solutions, it’s essential to understand why screws break in the first place. Common causes include:

- Over-tightening: Applying too much torque can shear the screw head or shank.

- Corrosion: Rust and corrosion weaken the metal, making it brittle and prone to breaking.

- Stripped threads: Using the wrong screwdriver or applying excessive force can strip the threads, preventing the screw from turning.

- Material fatigue: Repeated stress and vibration can weaken the screw over time.

- Poor quality screws: Inferior materials are more likely to break under stress.

Tools and Materials You’ll Need

Having the right tools on hand is crucial for successfully remove broken screw from metal. Here’s a list of essential items:

- Screw extractors: These specialized tools are designed to grip and turn broken screws.

- Drill: A power drill with various drill bits is necessary for creating pilot holes and using screw extractors.

- Screwdrivers: A set of screwdrivers, including flathead and Phillips head, in various sizes.

- Pliers: Needle-nose pliers and locking pliers (vise-grips) can be helpful for gripping and turning screw remnants.

- Penetrating oil: Lubricants like WD-40 or Liquid Wrench can help loosen corroded screws.

- Hammer: A small hammer can be used to gently tap the screw extractor into place.

- Center punch: Used to create a starting point for drilling.

- Safety glasses: Protecting your eyes is paramount.

- Gloves: Provide a better grip and protect your hands.

Methods to Remove a Broken Screw from Metal

Here are several methods you can try to remove broken screw from metal, starting with the simplest and progressing to more complex techniques:

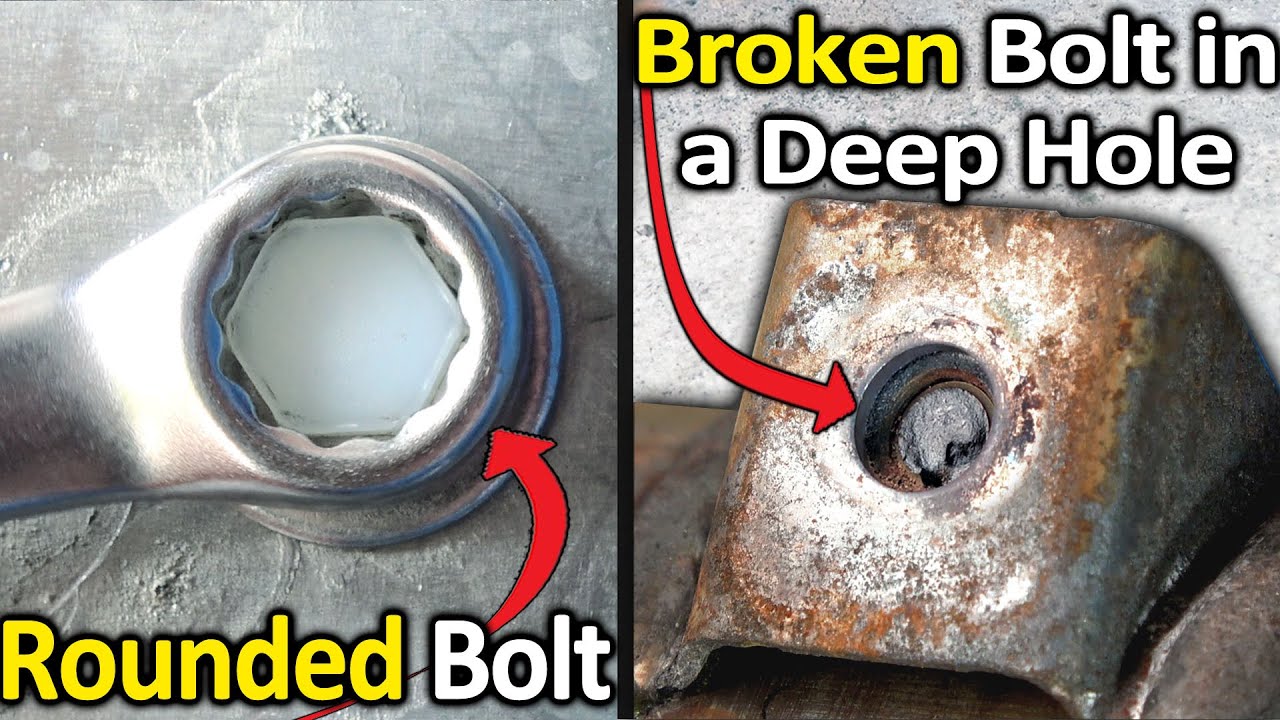

Method 1: Using a Screwdriver and Rubber Band

This method works best for screws with slightly stripped heads. Place a wide rubber band (like one from broccoli) over the screw head and then insert your screwdriver. The rubber band fills the gap and provides extra grip, allowing you to turn the screw. Apply steady pressure and turn slowly.

Method 2: Using a Screw Extractor Kit

Screw extractors are specifically designed to remove broken screw from metal. Here’s how to use them:

- Prepare the screw: Use a center punch to create a small indentation in the center of the broken screw. This will help guide the drill bit.

- Drill a pilot hole: Select a drill bit that is smaller than the screw extractor. Drill a pilot hole into the center of the broken screw. Be careful not to drill too deep or damage the surrounding metal.

- Insert the screw extractor: Insert the screw extractor into the pilot hole. Gently tap it with a hammer to ensure it’s securely seated.

- Turn the extractor: Use a wrench or pliers to turn the screw extractor counterclockwise. As you turn, the extractor will bite into the screw and begin to unscrew it.

- Remove the screw: Continue turning until the broken screw is completely removed.

Method 3: Using Locking Pliers (Vise-Grips)

If a portion of the screw head is still exposed, you can try using locking pliers to grip and turn it. Clamp the pliers tightly onto the screw head and turn counterclockwise. This method works best for screws that are not too tightly stuck.

Method 4: Using a Rotary Tool (Dremel)

A rotary tool with a cutting wheel can be used to create a slot in the screw head, allowing you to use a flathead screwdriver. Carefully cut a slot across the screw head, being mindful not to damage the surrounding metal. Then, insert a flathead screwdriver into the slot and turn counterclockwise.

Method 5: Applying Heat

Heat can help loosen corroded screws by expanding the metal. Use a heat gun or soldering iron to heat the area around the screw. Be careful not to overheat the metal, as this can cause damage. After heating, try using one of the other methods mentioned above to remove broken screw from metal.

Method 6: Using Penetrating Oil

Penetrating oil can help loosen screws that are stuck due to corrosion or rust. Apply the oil to the screw and let it sit for several hours or overnight. This will allow the oil to penetrate the threads and loosen the screw. After soaking, try using one of the other methods to remove broken screw from metal.

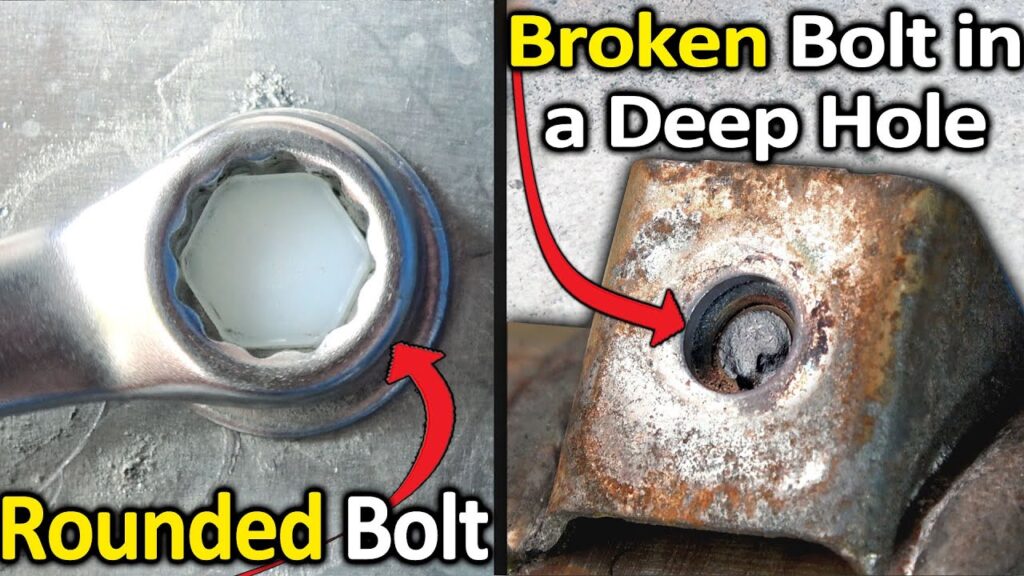

Method 7: Welding a Nut to the Broken Screw

This method requires welding skills and equipment. A nut is welded to the top of the broken screw, providing a new head that can be turned with a wrench. This method is particularly effective for deeply embedded or severely corroded screws. [See also: Welding Basics for Beginners]

Method 8: Drilling Out the Screw

As a last resort, you can drill out the screw completely. Start with a small drill bit and gradually increase the size until the screw head is removed. Be extremely careful not to damage the threads in the metal. Once the head is removed, you can use pliers to extract the remaining screw shank. This method should only be used when other methods have failed, as it can damage the threads and require you to re-tap the hole.

Tips for Preventing Broken Screws

Prevention is always better than cure. Here are some tips to avoid breaking screws in the first place:

- Use the right screwdriver: Ensure the screwdriver fits the screw head snugly. Using the wrong size or type can strip the threads.

- Apply steady pressure: Avoid applying excessive force. Let the tool do the work.

- Use lubricant: Apply penetrating oil to screws that are likely to be corroded.

- Pre-drill pilot holes: When working with hard materials, pre-drilling pilot holes can prevent screws from breaking.

- Use quality screws: Invest in high-quality screws made from durable materials.

- Avoid over-tightening: Tighten screws until they are snug, but avoid applying excessive torque.

Conclusion

Dealing with a remove broken screw from metal can be a challenging task, but with the right tools and techniques, it’s often possible to extract the screw without causing further damage. By understanding the causes of broken screws and following the methods outlined in this guide, you can increase your chances of success and get your project back on track. Remember to prioritize safety and take your time to avoid further complications. Good luck!

Mastering the art of how to remove broken screw from metal is a valuable skill for any DIY enthusiast or professional tradesperson. By understanding the underlying causes of screw breakage and employing the appropriate techniques, you can save time, money, and frustration. Whether you’re dealing with a stripped screw head, a corroded shank, or a completely snapped screw, there’s a method that can help you extract it successfully. Remember to always prioritize safety and take your time to avoid further damage. With practice and patience, you’ll become proficient at removing even the most stubborn broken screws.

Ultimately, the ability to remove broken screw from metal is a testament to your problem-solving skills and resourcefulness. So, the next time you encounter a broken screw, don’t despair. Instead, arm yourself with the knowledge and tools outlined in this guide and confidently tackle the challenge. You’ll be surprised at what you can accomplish with a little patience and ingenuity.