How to Get a Screw Out With a Broken Head: A Comprehensive Guide

Dealing with a screw that has a broken head can be incredibly frustrating. Whether you’re working on a DIY project, repairing furniture, or tackling a more complex task, a stripped or broken screw head can bring your progress to a screeching halt. Fortunately, there are several methods you can use to remove these stubborn fasteners without causing further damage. This guide provides a step-by-step approach to extracting screws with broken heads, covering various techniques and tools that can help you get the job done efficiently.

Understanding the Problem: Why Screw Heads Break

Before diving into the solutions, it’s essential to understand why screw heads break in the first place. Over-tightening is a common culprit, as is using the wrong type of screwdriver. The screw head can also be damaged by corrosion, wear and tear, or simply poor quality materials. Recognizing the cause can help you prevent similar issues in the future. Knowing how to get a screw out with a broken head is a valuable skill for any DIY enthusiast or professional.

Essential Tools for Removing Broken Screws

Having the right tools on hand is crucial for successfully removing a screw with a broken head. Here are some essentials:

- Screw Extractors: These specialized tools are designed to grip and remove damaged screws.

- Rubber Band or Steel Wool: These can provide extra grip between the screwdriver and the screw head.

- Pliers or Vise-Grips: Useful for gripping the screw head if there’s enough exposed.

- Screwdrivers: A variety of sizes and types (Phillips, flathead, etc.) are necessary.

- Drill: For creating a pilot hole or using screw extractors.

- Penetrating Oil: Helps to loosen corroded or stuck screws.

- Hammer: For gently tapping the screwdriver to improve grip.

Methods for Removing a Screw with a Broken Head

Using a Screw Extractor

A screw extractor is one of the most effective tools for removing a screw with a broken head. Here’s how to use one:

- Prepare the Screw: Use a center punch to create a starting point in the center of the broken screw head. This will help guide the drill bit.

- Drill a Pilot Hole: Using a drill bit slightly smaller than the screw extractor, drill a pilot hole into the screw head. Be careful to drill straight and not too deep.

- Insert the Screw Extractor: Place the screw extractor into the pilot hole. Some extractors require you to tap them in with a hammer to ensure a tight grip.

- Turn the Extractor: Using a wrench or T-handle, slowly turn the screw extractor counterclockwise. Apply steady pressure and avoid rushing. The extractor should bite into the screw and begin to turn it out.

- Remove the Screw: Continue turning until the screw is completely removed.

This method is particularly effective when you need to get a screw out with a broken head without causing further damage to the surrounding material. [See also: Choosing the Right Screw Extractor]

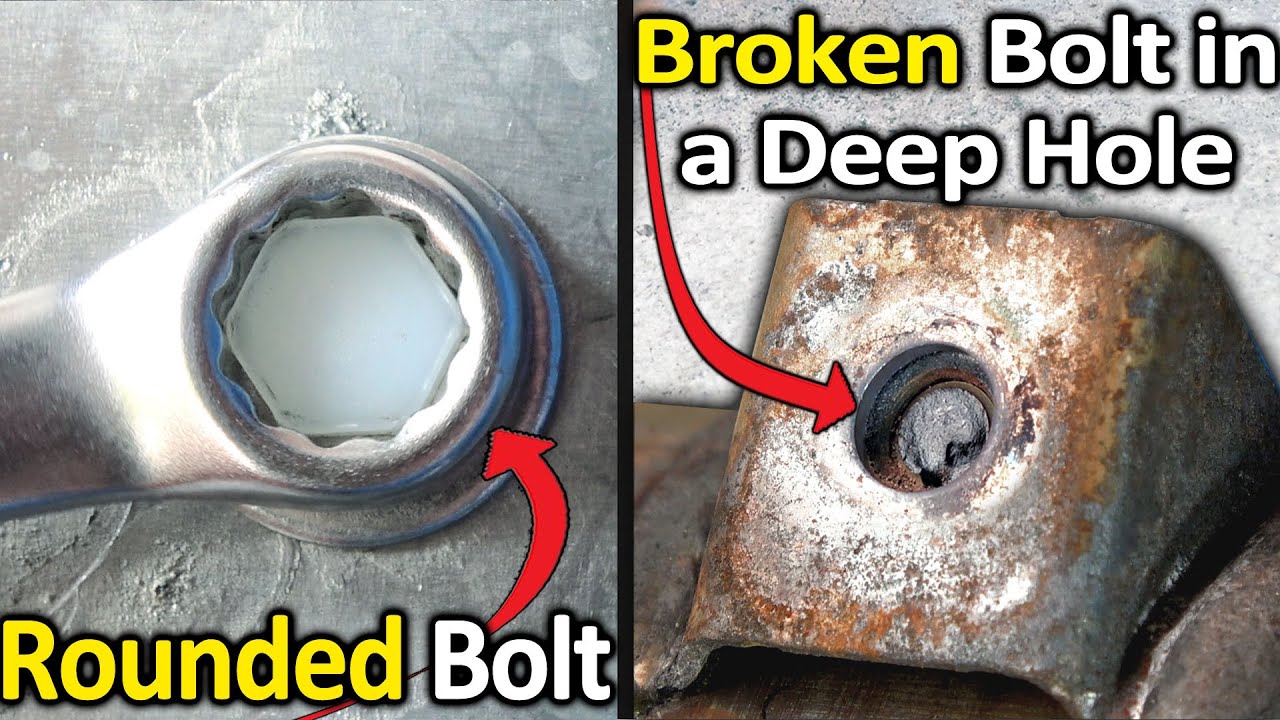

Using a Rubber Band or Steel Wool

If the screw head isn’t completely stripped but just difficult to grip, a rubber band or steel wool can provide extra friction:

- Place the Material: Place a wide rubber band or a small piece of steel wool over the screw head.

- Insert the Screwdriver: Insert the screwdriver into the screw head, pressing down firmly to ensure it grips the rubber band or steel wool.

- Turn Slowly: Turn the screwdriver slowly and steadily, applying consistent pressure. The added friction from the rubber band or steel wool can help the screwdriver grip the screw and turn it out.

This is a simple and often effective method for how to get a screw out with a broken head when the damage is minimal.

Using Pliers or Vise-Grips

If enough of the screw head is exposed, you can use pliers or vise-grips to grab onto it and turn it out:

- Grip the Screw Head: Firmly grip the exposed screw head with the pliers or vise-grips.

- Turn Counterclockwise: Turn the pliers or vise-grips counterclockwise, applying steady pressure. Be careful not to crush the screw head further.

- Remove the Screw: Continue turning until the screw is completely removed.

This method works best when the screw head is only partially damaged and there’s enough to grip. It’s a straightforward solution for how to get a screw out with a broken head if you have the right tools.

Creating a New Slot with a Rotary Tool

If the screw head is stripped but still has some material left, you can use a rotary tool (like a Dremel) to create a new slot for a flathead screwdriver:

- Prepare the Rotary Tool: Attach a cutting wheel to the rotary tool.

- Cut a Slot: Carefully cut a slot across the screw head, making it wide and deep enough to accommodate a flathead screwdriver.

- Use a Screwdriver: Insert a flathead screwdriver into the new slot and turn the screw counterclockwise to remove it.

This technique can be particularly useful when you need to get a screw out with a broken head and other methods have failed. [See also: Rotary Tool Safety Tips]

Using Penetrating Oil

Sometimes, the screw is simply stuck due to rust or corrosion. In this case, penetrating oil can help:

- Apply Penetrating Oil: Apply penetrating oil to the screw head and let it soak for several minutes (or even hours for heavily corroded screws).

- Tap Gently: Gently tap the screw head with a hammer to help the oil penetrate.

- Try Removing the Screw: Use a screwdriver or pliers to try removing the screw. The penetrating oil should help loosen it.

This is a helpful preliminary step for how to get a screw out with a broken head, especially in older projects.

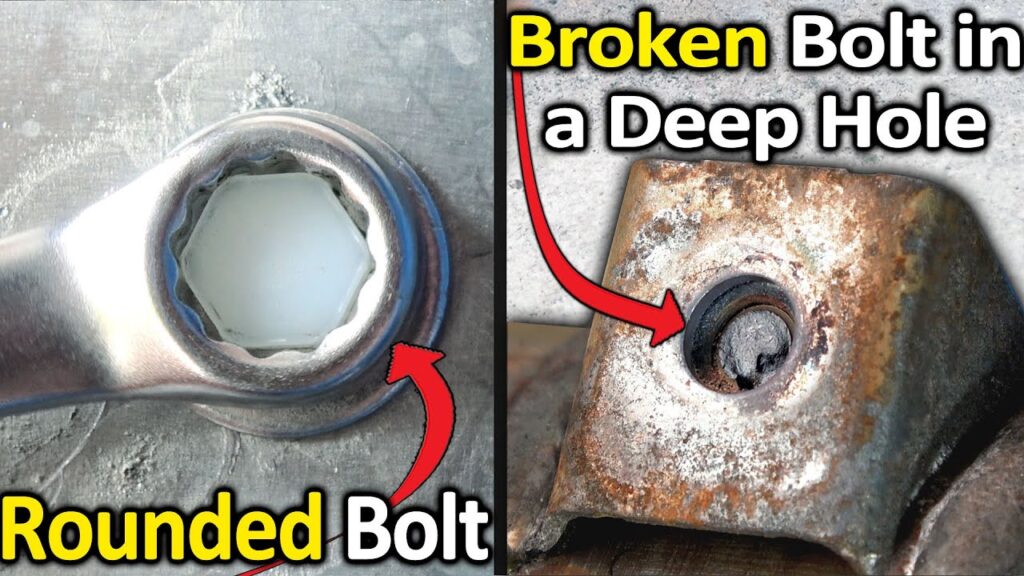

Welding a Nut to the Screw Head

This method is more advanced and requires welding equipment, but it can be very effective for severely damaged screws:

- Position the Nut: Place a nut over the broken screw head.

- Weld the Nut: Weld the nut to the screw head, creating a strong bond.

- Turn the Nut: Use a wrench to turn the nut counterclockwise, which will turn the screw out.

This approach provides a solid grip and is ideal for situations where you need to get a screw out with a broken head and other methods are not feasible.

Tips for Preventing Broken Screw Heads

Prevention is always better than cure. Here are some tips to avoid breaking screw heads in the first place:

- Use the Right Screwdriver: Ensure you’re using the correct type and size of screwdriver for the screw.

- Apply Steady Pressure: Apply steady, even pressure when turning the screwdriver.

- Avoid Over-Tightening: Be careful not to over-tighten screws, especially in soft materials.

- Use Lubricant: For tough screws, apply a small amount of lubricant to help them turn more easily.

- Pre-Drill Pilot Holes: When working with hard materials, pre-drill pilot holes to prevent screws from snapping.

Conclusion

Knowing how to get a screw out with a broken head is an invaluable skill for anyone who works with tools or does DIY projects. By using the right tools and techniques, you can remove even the most stubborn screws without causing further damage. Whether you opt for a screw extractor, a rubber band, or a more advanced method like welding, the key is to be patient and methodical. With the right approach, you can overcome this common challenge and keep your projects moving forward. Remember to always prioritize safety and use appropriate protective gear when working with tools.