How to Extract a Screw with a Broken Head: A Comprehensive Guide

Dealing with a screw with a broken head can be incredibly frustrating. Whether you’re working on a DIY project, repairing furniture, or tackling a more complex task, a stripped or broken screw head can bring your progress to a screeching halt. This comprehensive guide provides you with several proven methods on how to extract a screw with a broken head, ensuring you can overcome this common challenge and get back to work efficiently.

Understanding the Problem

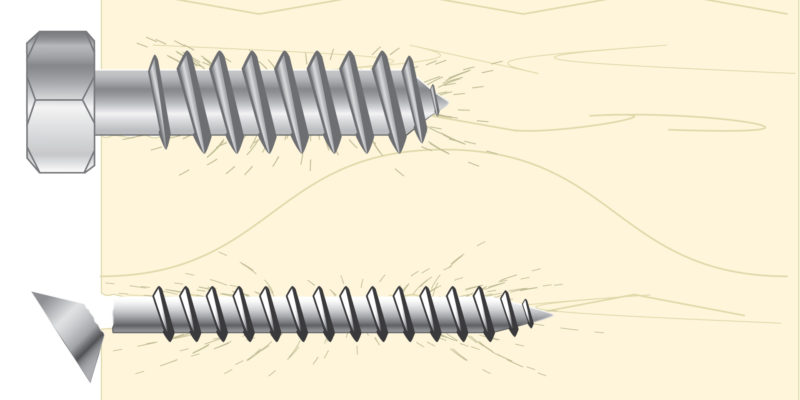

Before diving into the solutions, it’s crucial to understand why screw heads break in the first place. Over-tightening, using the wrong size screwdriver, or working with low-quality screws are common culprits. Rust and corrosion can also weaken the screw head over time. Recognizing the cause can help you prevent similar issues in the future. Knowing how to extract a screw with a broken head relies on understanding its current state and the material it’s embedded in.

Essential Tools and Materials

Having the right tools at your disposal is half the battle. Here’s a list of items you might need when learning how to extract a screw with a broken head:

- Screw extractors (various sizes)

- Drill with a variety of bits

- Rubber band

- Wide rubber band

- Screwdriver (various sizes and types)

- Pliers (needle-nose and locking pliers)

- Penetrating oil (e.g., WD-40)

- Hammer

- Center punch

- Heat gun or soldering iron (optional)

Methods for Extracting Screws with Broken Heads

Here are several methods you can try, ranging from simple to more complex. The best approach depends on the severity of the damage and the type of material the screw is embedded in.

The Rubber Band Trick

This is often the first and simplest method to try. Place a wide rubber band over the stripped screw head. The rubber band fills the gap between the screwdriver and the screw head, providing extra grip. Press down firmly with the screwdriver and try to unscrew it slowly. This method often works for minor stripping. If you’re lucky, this simple trick is all you need to learn how to extract a screw with a broken head.

Using a Screw Extractor

A screw extractor is a specialized tool designed for removing damaged screws. Here’s how to use one:

- Prepare the Screw: Use a center punch to create a small indentation in the center of the broken screw head. This helps guide the drill bit.

- Drill a Pilot Hole: Select a drill bit that’s slightly smaller than the screw extractor. Drill a pilot hole into the screw head. Be careful not to drill too deep.

- Insert the Screw Extractor: Insert the screw extractor into the pilot hole. Apply firm, even pressure while turning the extractor counterclockwise. The extractor’s threads will bite into the screw, allowing you to unscrew it.

- Extract the Screw: Continue turning the extractor until the screw is completely removed.

Screw extractors are a reliable method for learning how to extract a screw with a broken head, especially when other techniques fail.

Using Pliers

If enough of the screw head is exposed, you might be able to grip it with pliers. Locking pliers (vise-grips) are particularly effective. Clamp the pliers tightly onto the screw head and turn counterclockwise. This method requires a firm grip and may not work if the screw is deeply embedded or severely damaged. This can be a straightforward method of how to extract a screw with a broken head if the conditions are right.

Creating a New Slot with a Rotary Tool

If the screw head is only partially stripped, you can use a rotary tool (like a Dremel) with a cutting wheel to create a new slot for a flathead screwdriver. Carefully cut a slot across the screw head, being mindful not to damage the surrounding material. Once the slot is created, use a flathead screwdriver to unscrew the screw. This method is useful when learning how to extract a screw with a broken head without resorting to more aggressive techniques.

Applying Heat

Heat can help loosen a corroded or stuck screw. Use a heat gun or soldering iron to heat the screw head for a few minutes. The heat will expand the metal, breaking the bond between the screw and the surrounding material. After heating, try using one of the other extraction methods, such as the rubber band trick or pliers. Be cautious when using heat, especially near flammable materials. Understanding how to extract a screw with a broken head often involves knowing how to deal with corrosion.

Using a Hammer and Screwdriver

Sometimes, a sharp impact can help loosen a stubborn screw. Place the tip of a screwdriver into the stripped screw head and gently tap the end of the screwdriver with a hammer. This can help the screwdriver get a better grip. Then, apply pressure and try to unscrew the screw. This method is best used in conjunction with other techniques. Knowing how to extract a screw with a broken head requires understanding the mechanics of loosening a stuck fastener.

Penetrating Oil

Penetrating oil, such as WD-40, can help loosen a corroded or stuck screw. Apply the oil to the screw head and let it sit for several minutes (or even hours) to penetrate the threads. Then, try using one of the extraction methods described above. Penetrating oil is a valuable tool when learning how to extract a screw with a broken head, especially in older structures.

Drilling the Screw Out

As a last resort, you can drill the screw out completely. Use a drill bit that’s slightly smaller than the diameter of the screw. Carefully drill through the screw head, gradually increasing the drill bit size until the head separates from the shank. Once the head is removed, you can often remove the remaining shank with pliers or by using a screw extractor. This method should be used with caution to avoid damaging the surrounding material. While not ideal, drilling the screw out is sometimes the only way to learn how to extract a screw with a broken head in extremely difficult cases.

Prevention is Key

The best way to deal with a broken screw head is to prevent it from happening in the first place. Here are a few tips:

- Use the Right Screwdriver: Always use a screwdriver that’s the correct size and type for the screw.

- Apply Even Pressure: When screwing, apply even pressure and avoid tilting the screwdriver.

- Avoid Over-Tightening: Over-tightening is a common cause of stripped screw heads.

- Use High-Quality Screws: Investing in high-quality screws can save you time and frustration in the long run.

- Lubricate Screws: Lubricating screws, especially when working with hardwoods or metal, can prevent them from seizing up.

Conclusion

Dealing with a screw with a broken head doesn’t have to be a project-stopping disaster. By understanding the problem, having the right tools, and employing the appropriate extraction methods, you can successfully remove even the most stubborn screws. Remember to take your time, be patient, and don’t be afraid to try different techniques. With a little perseverance, you’ll master the art of how to extract a screw with a broken head and keep your projects moving forward. [See also: Removing Stripped Screws] [See also: Best Screwdriver Sets for Home Improvement]