Bicycle Hydraulic Brakes Maintenance: A Comprehensive Guide

Hydraulic brakes on bicycles offer superior stopping power and modulation compared to traditional cable brakes. However, like all mechanical systems, they require regular maintenance to ensure optimal performance and longevity. This comprehensive guide will walk you through the essential aspects of bicycle hydraulic brakes maintenance, covering everything from routine checks to bleeding procedures and troubleshooting common issues.

Understanding Bicycle Hydraulic Brakes

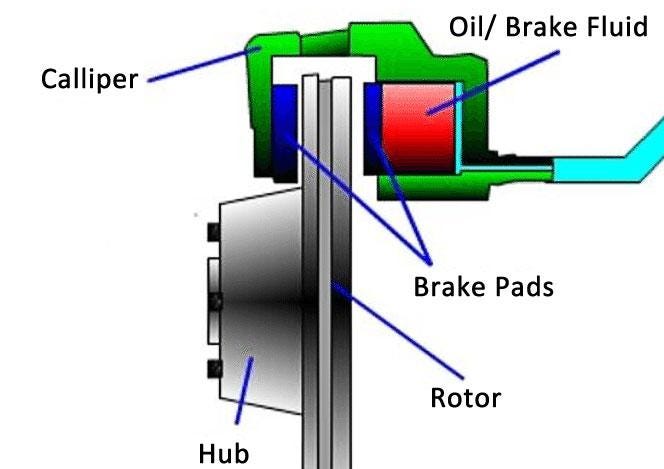

Before diving into the maintenance process, it’s crucial to understand how hydraulic brakes work. These systems use a fluid-filled line to transmit force from the brake lever to the calipers, which then squeeze the brake pads against the rotor. The key components include:

- Brake Lever: The interface for the rider to apply braking force.

- Master Cylinder: Located at the brake lever, it contains a piston that pushes fluid into the brake line.

- Brake Line (Hose): Connects the master cylinder to the caliper, carrying the hydraulic fluid.

- Caliper: Houses the pistons that push the brake pads against the rotor.

- Brake Pads: Friction material that contacts the rotor to slow the bicycle.

- Rotor: A metal disc attached to the wheel hub that the brake pads grip.

- Hydraulic Fluid: The medium that transmits force throughout the system. DOT fluid or mineral oil are most common.

Choosing the correct hydraulic fluid is paramount. Never mix DOT fluid and mineral oil. DOT fluid is hygroscopic, meaning it absorbs moisture from the air, which can degrade its performance over time. Mineral oil is not hygroscopic but can be affected by extreme temperatures. Always refer to your brake manufacturer’s specifications for the recommended fluid type.

Routine Bicycle Hydraulic Brakes Maintenance

Regular maintenance is key to preventing problems and extending the life of your bicycle hydraulic brakes. Here’s a checklist of routine tasks:

Visual Inspection

Regularly inspect your brake system for any signs of damage or leaks. Check the brake lines for cracks, kinks, or bulges. Examine the calipers and master cylinder for any fluid leaks around the seals. Also, inspect the rotors for warping or damage.

Brake Pad Inspection and Replacement

Brake pads wear down over time and need to be replaced. Check the pad thickness regularly. Most brake pads have wear indicators or minimum thickness markings. If the pads are worn down to the minimum thickness, replace them immediately. Riding with worn brake pads can damage the rotors and compromise braking performance.

To replace brake pads:

- Remove the wheel from the bicycle.

- Remove the brake caliper from the fork or frame.

- Remove the retaining bolt or clip that holds the brake pads in place.

- Slide out the old brake pads.

- Install the new brake pads.

- Reinstall the retaining bolt or clip.

- Reinstall the caliper and wheel.

- Pump the brake lever several times to ensure the pads are properly seated against the rotor.

Cleaning the Brakes

Keep your brakes clean to ensure optimal performance. Use a dedicated brake cleaner or isopropyl alcohol to clean the rotors and calipers. Avoid using degreasers or lubricants on the braking surfaces, as they can contaminate the brake pads and reduce braking power. Periodically cleaning your bicycle hydraulic brakes can prevent squealing and improve responsiveness.

Lever and Caliper Adjustment

Ensure the brake levers are properly adjusted for reach and feel. Most brake levers have reach adjustment screws that allow you to customize the distance between the lever and the handlebar. Also, check that the calipers are properly aligned with the rotor. If the calipers are misaligned, they can cause the brake pads to rub against the rotor, leading to premature wear and reduced braking performance.

Bleeding Bicycle Hydraulic Brakes

Bleeding the brakes is a crucial part of bicycle hydraulic brakes maintenance. Over time, air can enter the brake lines, reducing braking power and creating a spongy feel at the lever. Bleeding the brakes removes the air and restores optimal braking performance.

When to Bleed Your Brakes

You should bleed your brakes if you notice any of the following:

- A spongy or soft feel at the brake lever.

- Reduced braking power.

- The brake lever pulls all the way to the handlebar.

- You have recently replaced brake lines or calipers.

Bleeding Procedure

The bleeding procedure varies slightly depending on the brake manufacturer. However, the general steps are as follows:

- Gather the necessary tools: bleed kit (syringe, tubing, fittings), appropriate hydraulic fluid, wrench, and rags.

- Prepare the bicycle: position the bicycle so that the master cylinder is higher than the caliper.

- Attach the bleed kit: connect the syringe and tubing to the bleed ports on the master cylinder and caliper.

- Open the bleed ports: loosen the bleed screws on the master cylinder and caliper.

- Push fluid through the system: use the syringe to push fluid from the caliper to the master cylinder, forcing air bubbles out of the system.

- Close the bleed ports: tighten the bleed screws on the master cylinder and caliper.

- Remove the bleed kit: disconnect the syringe and tubing.

- Clean up any spilled fluid: use a rag to wipe up any spilled hydraulic fluid.

- Test the brakes: pump the brake lever several times to ensure the brakes are working properly.

Refer to your brake manufacturer’s instructions for specific bleeding procedures and torque specifications. Improper bleeding can result in brake failure.

Troubleshooting Common Issues with Bicycle Hydraulic Brakes

Even with regular maintenance, you may encounter problems with your bicycle hydraulic brakes. Here are some common issues and their solutions:

Squealing Brakes

Squealing brakes are a common problem, often caused by contaminated brake pads or rotors. Clean the rotors and brake pads with a dedicated brake cleaner. If the squealing persists, try lightly sanding the brake pads with fine-grit sandpaper. If the pads are heavily contaminated, they may need to be replaced.

Spongy Brakes

Spongy brakes are usually caused by air in the brake lines. Bleed the brakes to remove the air and restore a firm lever feel.

Brake Lever Pulls to the Handlebar

This can be caused by air in the brake lines, worn brake pads, or a leak in the system. Bleed the brakes, check the brake pad thickness, and inspect the brake lines and calipers for leaks.

Brake Lockup

Brake lockup can be caused by a seized piston in the caliper or a problem with the master cylinder. Disassemble the caliper and clean the pistons. If the problem persists, you may need to replace the caliper or master cylinder.

Leaking Brakes

Leaks can occur at the brake lines, calipers, or master cylinder. Inspect the system for any signs of fluid leaks. Tighten any loose fittings. If the leak persists, you may need to replace the affected component.

Advanced Bicycle Hydraulic Brakes Maintenance

For more advanced bicycle hydraulic brakes maintenance, consider the following:

Caliper Rebuild

Over time, the seals in the calipers can wear out, leading to leaks or reduced braking performance. Rebuilding the calipers involves disassembling them, cleaning the components, and replacing the seals. This requires specialized tools and knowledge.

Brake Line Replacement

Brake lines can become damaged or worn over time. Replacing the brake lines involves disconnecting them from the master cylinder and calipers, installing new lines, and bleeding the brakes.

Master Cylinder Rebuild

Similar to calipers, the master cylinder can also be rebuilt to replace worn seals and restore optimal performance. This is a more complex procedure and should only be attempted by experienced mechanics.

Tools and Supplies for Bicycle Hydraulic Brakes Maintenance

Having the right tools and supplies is essential for performing bicycle hydraulic brakes maintenance. Here’s a list of essential items:

- Brake bleed kit (syringe, tubing, fittings)

- Hydraulic fluid (DOT fluid or mineral oil)

- Wrenches

- Screwdrivers

- Brake cleaner

- Rags

- Brake pad spreader

- Torque wrench

- Gloves

- Safety glasses

Conclusion

Maintaining your bicycle hydraulic brakes is crucial for ensuring safe and reliable braking performance. By following the tips and procedures outlined in this guide, you can keep your brakes in top condition and enjoy confident riding. Remember to always consult your brake manufacturer’s instructions for specific recommendations and procedures. Regular maintenance and prompt attention to any issues will extend the life of your brakes and provide you with years of reliable service. [See also: Replacing Bicycle Brake Pads] [See also: Understanding Bicycle Brake Systems]