Inland Spring and Axle: A Comprehensive Guide to Suspension and Drivetrain Components

The automotive industry relies on a complex interplay of components to ensure vehicles operate safely and efficiently. Among these, the suspension and drivetrain systems are paramount. Within these systems, inland spring and axle manufacturers play a crucial role in providing the parts that contribute to a smooth ride and reliable power transfer. This article delves into the world of inland spring and axle components, exploring their functions, types, and importance in various vehicle applications. We’ll examine how these parts contribute to overall vehicle performance and longevity.

Understanding Vehicle Suspension Systems

A vehicle’s suspension system is designed to absorb shocks and vibrations from the road, providing a comfortable ride for passengers and maintaining tire contact with the road surface for optimal handling. Key components of the suspension system include springs, shock absorbers, struts, and linkages. Inland spring and axle suppliers often specialize in providing high-quality springs that meet the specific demands of different vehicle types, from light-duty cars to heavy-duty trucks.

Types of Springs

Several types of springs are commonly used in vehicle suspension systems:

- Coil Springs: These are helical springs that compress under load, providing a linear spring rate. They are commonly found in passenger cars and light trucks.

- Leaf Springs: These consist of multiple layers of steel strips stacked together, providing a progressive spring rate. They are typically used in heavy-duty vehicles like trucks and vans due to their ability to handle heavy loads.

- Torsion Bars: These are long, slender bars that twist under load, providing a spring force. They are sometimes used in independent suspension systems.

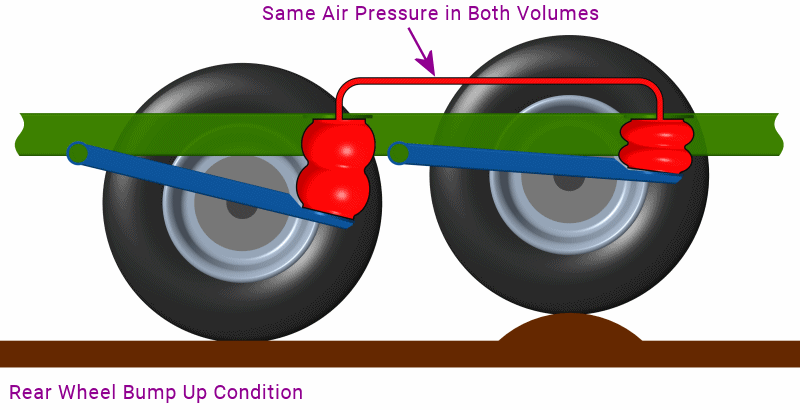

- Air Springs: These use compressed air to provide a variable spring rate, allowing for adjustable ride height and load carrying capacity. They are often found in luxury vehicles and heavy-duty trucks.

The choice of spring type depends on the vehicle’s intended use and the desired ride characteristics. Inland spring and axle manufacturers offer a wide range of springs to meet these diverse needs.

Exploring Vehicle Drivetrain Systems

The drivetrain is responsible for transmitting power from the engine to the wheels, enabling the vehicle to move. Key components of the drivetrain include the transmission, driveshaft, differential, and axles. The axle is a critical component that connects the wheels to the differential, transmitting torque and supporting the vehicle’s weight. Inland spring and axle companies often manufacture and supply robust axles designed to withstand the stresses of daily driving and heavy-duty applications.

Types of Axles

Axles can be categorized based on their location and function:

- Front Axles: These axles are located at the front of the vehicle and are responsible for steering and supporting the vehicle’s weight. In front-wheel-drive vehicles, the front axles also transmit power to the wheels.

- Rear Axles: These axles are located at the rear of the vehicle and transmit power to the wheels in rear-wheel-drive and four-wheel-drive vehicles.

- Drive Axles: These axles transmit power from the differential to the wheels.

- Dead Axles: These axles do not transmit power but simply support the vehicle’s weight. They are often found in trailers and some heavy-duty trucks.

The design and construction of an axle are crucial for ensuring reliable performance and durability. Inland spring and axle specialists understand the importance of using high-quality materials and precise manufacturing processes to produce axles that can withstand the rigors of the road. [See also: Automotive Axle Repair and Maintenance]

The Importance of Quality Inland Spring and Axle Components

The quality of inland spring and axle components directly impacts a vehicle’s performance, safety, and longevity. Using substandard or worn-out parts can lead to a variety of problems, including:

- Poor Handling: Worn springs and axles can compromise a vehicle’s handling, making it difficult to control in emergency situations.

- Reduced Ride Comfort: Damaged suspension components can result in a harsh and uncomfortable ride.

- Increased Tire Wear: Misaligned or worn suspension parts can cause uneven tire wear, leading to premature tire replacement.

- Mechanical Failures: Overstressed axles can break, resulting in a loss of power and potentially dangerous situations.

- Safety Risks: Compromised suspension and drivetrain components can increase the risk of accidents.

Therefore, it is essential to use high-quality inland spring and axle components from reputable manufacturers to ensure optimal vehicle performance and safety. Regular inspection and maintenance of these components are also crucial for preventing problems and extending the life of your vehicle. Choosing a trusted inland spring and axle supplier is key to maintaining vehicle integrity.

Factors to Consider When Choosing Inland Spring and Axle Components

When selecting inland spring and axle components, several factors should be considered:

- Vehicle Type: The type of vehicle will determine the appropriate spring and axle specifications. Light-duty cars require different components than heavy-duty trucks.

- Load Capacity: The intended load carrying capacity of the vehicle should be considered when selecting springs and axles. Heavier loads require stronger components.

- Driving Conditions: The types of roads and driving conditions the vehicle will be subjected to should be taken into account. Off-road driving requires more durable components.

- Quality and Durability: Choose components made from high-quality materials and manufactured to exacting standards.

- Manufacturer Reputation: Select components from reputable manufacturers with a proven track record of producing reliable parts.

- Warranty: Look for components that are backed by a comprehensive warranty.

By carefully considering these factors, you can ensure that you choose the right inland spring and axle components for your vehicle.

Maintenance and Inspection of Inland Spring and Axle Components

Regular maintenance and inspection are essential for ensuring the longevity and reliability of inland spring and axle components. Key maintenance tasks include:

- Visual Inspection: Regularly inspect springs and axles for signs of damage, such as cracks, bends, or corrosion.

- Lubrication: Lubricate axle bearings and other moving parts to reduce friction and wear.

- Alignment: Ensure that the wheels are properly aligned to prevent uneven tire wear and handling problems.

- Torque Checks: Regularly check and tighten axle nuts and bolts to ensure proper clamping force.

- Professional Inspections: Have a qualified mechanic inspect your suspension and drivetrain systems periodically to identify potential problems early on.

By following these maintenance guidelines, you can help extend the life of your inland spring and axle components and ensure the safe and reliable operation of your vehicle. Ignoring these components can lead to costly repairs and potentially dangerous situations. Proper maintenance of your inland spring and axle system is a critical investment in the long-term health of your vehicle.

The Future of Inland Spring and Axle Technology

The automotive industry is constantly evolving, and inland spring and axle technology is no exception. Future trends in this area include:

- Lightweight Materials: The use of lightweight materials, such as aluminum and composites, to reduce vehicle weight and improve fuel efficiency.

- Advanced Suspension Systems: The development of more sophisticated suspension systems, such as active suspension and air suspension, to provide improved ride quality and handling.

- Electric Vehicle Applications: The design of axles and suspension components specifically for electric vehicles, which have different weight distribution and power delivery characteristics than traditional gasoline-powered vehicles.

- Smart Axle Technology: Integration of sensors and electronics into axles to monitor performance and provide real-time feedback to the driver.

These advancements will continue to improve the performance, safety, and efficiency of vehicles, making inland spring and axle technology an important area of innovation. As vehicles become more sophisticated, the demands on inland spring and axle components will only increase, driving further advancements in materials, design, and manufacturing processes. The future looks bright for inland spring and axle innovation.

Finding a Reliable Inland Spring and Axle Supplier

Choosing the right supplier for your inland spring and axle needs is crucial. Look for a supplier that offers:

- A wide range of products: Ensure the supplier offers a comprehensive selection of springs and axles to meet your specific needs.

- High-quality components: Prioritize suppliers that use high-quality materials and adhere to strict manufacturing standards.

- Competitive pricing: Compare prices from different suppliers to ensure you are getting a fair deal.

- Excellent customer service: Choose a supplier that provides responsive and helpful customer service.

- Technical expertise: Look for a supplier with knowledgeable staff who can provide technical assistance and guidance.

By carefully evaluating potential suppliers, you can find a partner that will provide you with the high-quality inland spring and axle components you need to keep your vehicles running smoothly and safely. Remember to always prioritize quality and reliability when selecting these critical components. A dependable inland spring and axle system is essential for any vehicle’s optimal performance and longevity. [See also: Choosing the Right Suspension System]

In conclusion, inland spring and axle components are essential for ensuring the safe, comfortable, and reliable operation of vehicles. By understanding the function, types, and importance of these components, you can make informed decisions about their selection, maintenance, and replacement. Choosing high-quality parts from reputable manufacturers and following proper maintenance practices will help you keep your vehicles running smoothly for years to come. The world of inland spring and axle technology is constantly evolving, so staying informed about the latest advancements is crucial for both vehicle owners and industry professionals.