CRC Lube with PTFE: The Ultimate Guide to Enhanced Performance and Protection

In the world of industrial maintenance, automotive care, and even household applications, lubrication plays a pivotal role in ensuring smooth operation, reducing wear and tear, and extending the lifespan of machinery and equipment. Among the myriad of lubricants available, CRC Lube with PTFE stands out as a versatile and high-performance solution. This comprehensive guide delves into the intricacies of CRC Lube with PTFE, exploring its unique properties, diverse applications, and the benefits it offers across various industries.

Understanding CRC Lube with PTFE

CRC Lube with PTFE is a synthetic lubricant fortified with Polytetrafluoroethylene (PTFE), commonly known as Teflon. This combination creates a product that offers exceptional lubrication, protection, and performance in a wide range of conditions. The PTFE component significantly reduces friction, prevents sticking, and provides a non-reactive barrier against various chemicals and environmental factors. This makes CRC Lube with PTFE an indispensable tool for professionals and DIY enthusiasts alike.

The Science Behind PTFE

PTFE is a fluorocarbon solid, meaning it consists entirely of carbon and fluorine atoms. This unique composition gives it remarkable properties, including:

- Low Coefficient of Friction: PTFE has one of the lowest coefficients of friction of any solid material, making it incredibly slippery.

- Chemical Inertness: It is virtually unaffected by most chemicals, including acids, bases, and solvents.

- High Temperature Resistance: PTFE can withstand temperatures up to 260°C (500°F) without degrading.

- Non-Stick Properties: Nothing sticks to PTFE, making it ideal for applications where adhesion is undesirable.

When combined with a high-quality lubricant base, PTFE enhances the overall performance, durability, and versatility of the product, resulting in CRC Lube with PTFE.

Key Features and Benefits of CRC Lube with PTFE

CRC Lube with PTFE offers a multitude of benefits, making it a preferred choice for various applications:

- Superior Lubrication: The combination of synthetic lubricant and PTFE provides excellent lubrication, reducing friction and wear on moving parts.

- Enhanced Protection: It forms a protective barrier against rust, corrosion, and oxidation, extending the lifespan of equipment and machinery.

- Wide Temperature Range: CRC Lube with PTFE performs effectively in a broad temperature range, from extreme cold to high heat.

- Water Resistance: It repels water and moisture, preventing corrosion and ensuring consistent performance in wet environments.

- Versatile Applications: From automotive parts to industrial machinery, CRC Lube with PTFE can be used in a wide range of applications.

- Reduces Noise and Vibration: By minimizing friction, it helps reduce noise and vibration in moving parts, creating a smoother and quieter operation.

- Long-Lasting Performance: The PTFE component ensures that the lubricant remains effective for an extended period, reducing the need for frequent reapplication.

Applications of CRC Lube with PTFE

The versatility of CRC Lube with PTFE makes it suitable for a wide array of applications across different industries:

Automotive Industry

In the automotive sector, CRC Lube with PTFE is used for:

- Door Hinges and Locks: Ensures smooth operation and prevents sticking.

- Window Regulators: Reduces friction and extends the lifespan of window mechanisms.

- Cable and Linkage Systems: Provides lubrication and protection against corrosion.

- Brake Calipers: Prevents sticking and ensures proper brake function.

- Suspension Components: Reduces friction and noise in suspension systems.

Industrial Applications

In industrial settings, CRC Lube with PTFE is used for:

- Conveyor Systems: Ensures smooth and efficient operation of conveyor belts and rollers.

- Gears and Bearings: Reduces friction and wear in gears and bearings, extending their lifespan.

- Chains and Cables: Provides lubrication and protection against corrosion.

- Valves and Fittings: Prevents sticking and ensures proper sealing.

- Manufacturing Equipment: Maintains optimal performance of various manufacturing machines.

Household Uses

CRC Lube with PTFE is also useful around the house for:

- Door Hinges and Locks: Eliminates squeaks and ensures smooth operation.

- Garage Door Tracks: Reduces friction and noise in garage door systems.

- Window Tracks: Ensures smooth opening and closing of windows.

- Tools and Equipment: Protects tools and equipment from rust and corrosion.

- Bicycles: Lubricates chains and gears for smooth and efficient riding.

How to Apply CRC Lube with PTFE

Applying CRC Lube with PTFE is a straightforward process, but following these steps will ensure optimal results:

- Clean the Surface: Before applying the lubricant, clean the surface to remove any dirt, grease, or debris.

- Shake Well: Shake the can of CRC Lube with PTFE thoroughly to ensure proper mixing of the lubricant and PTFE particles.

- Apply Sparingly: Apply a thin, even coat of the lubricant to the area that needs lubrication. Avoid over-application, as this can attract dirt and debris.

- Allow to Penetrate: Allow the lubricant to penetrate the surface for a few minutes.

- Wipe Away Excess: Wipe away any excess lubricant with a clean cloth.

Safety Precautions

While CRC Lube with PTFE is generally safe to use, it is essential to follow these safety precautions:

- Ventilation: Use in a well-ventilated area to avoid inhaling fumes.

- Eye Protection: Wear safety glasses or goggles to protect your eyes from splashes.

- Skin Protection: Wear gloves to prevent skin contact.

- Flammability: Keep away from open flames and sources of ignition.

- Storage: Store in a cool, dry place away from direct sunlight.

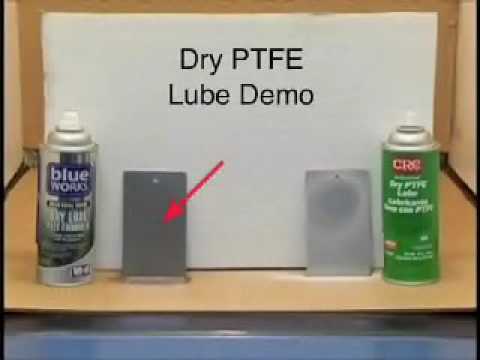

Comparing CRC Lube with PTFE to Other Lubricants

While there are many types of lubricants available, CRC Lube with PTFE offers distinct advantages over traditional options. For example, compared to petroleum-based lubricants, CRC Lube with PTFE provides superior resistance to temperature extremes and chemical degradation. Unlike silicone-based lubricants, it does not attract dust and dirt, making it ideal for applications where cleanliness is essential. Its unique formulation provides a longer-lasting and more effective solution compared to many general-purpose lubricants.

The Future of Lubrication: Why Choose CRC Lube with PTFE

As technology advances and machinery becomes more sophisticated, the demand for high-performance lubricants will continue to grow. CRC Lube with PTFE is well-positioned to meet these demands, offering a combination of superior lubrication, protection, and versatility. Its ability to reduce friction, prevent corrosion, and withstand extreme conditions makes it an essential tool for maintaining the efficiency and longevity of equipment and machinery across various industries. [See also: Choosing the Right Lubricant for Your Needs]

Conclusion

CRC Lube with PTFE is a powerful and versatile lubricant that offers a wide range of benefits for automotive, industrial, and household applications. Its unique combination of synthetic lubricant and PTFE provides superior lubrication, protection, and performance in diverse conditions. By understanding its properties, applications, and safety precautions, you can effectively utilize CRC Lube with PTFE to enhance the performance and longevity of your equipment and machinery. Whether you are a professional mechanic, an industrial maintenance worker, or a DIY enthusiast, CRC Lube with PTFE is a valuable addition to your toolkit.